With the Centodieci, Bugatti pays homage to the legendary EB 110. Only ten cars in the Few-off project are being built for an exclusive clientele, all of whom had made their bookings within hours of the concept model being presented at ‘The Quail – A Motorsports Gathering’ in California in mid-2019. Last year, further work was limited due to the pandemic conditions but now the company is building the first prototype of the hyper sportscar which has a starting price from 8 million euros (about RM39.2 million).

The design of the Centodieci with the flat front, deep-seated front spoiler and 3-part air inlets reinterprets the shape of the super sportscar of the 1990s. The EB 110 was an important milestone on the way to revitalizing the Bugatti brand in 1998, leading to the first modern hyper sports car, the Veyron.

Modern interpretation of EB 110

It was the Italian entrepreneur Romano Artioli and the star architect Giampaolo Benedini who created the EB 110 around 30 years ago. “It was a challenge for us not to get caught up in the design of the legendary EB 110 and to only work in the retrospective. We wanted to create a modern interpretation of the form and technology of the time. At the same time, we couldn’t lose the charm and character of the EB 110. Because the super sportscar is still fascinating today with its special design and technology, ”said Achim Anscheidt, chief designer at Bugatti.

Since the premiere of the Centodieci, the Bugatti development team has been working on the technical implementation of the strictly limited model. “Every newly developed vehicle is an immense challenge, as we develop a small series that must also meet and even exceed all quality and safety standards of a large series,” explained Andre Kullig, technical project manager for one- and few-off projects at Bugatti.

Complex development process

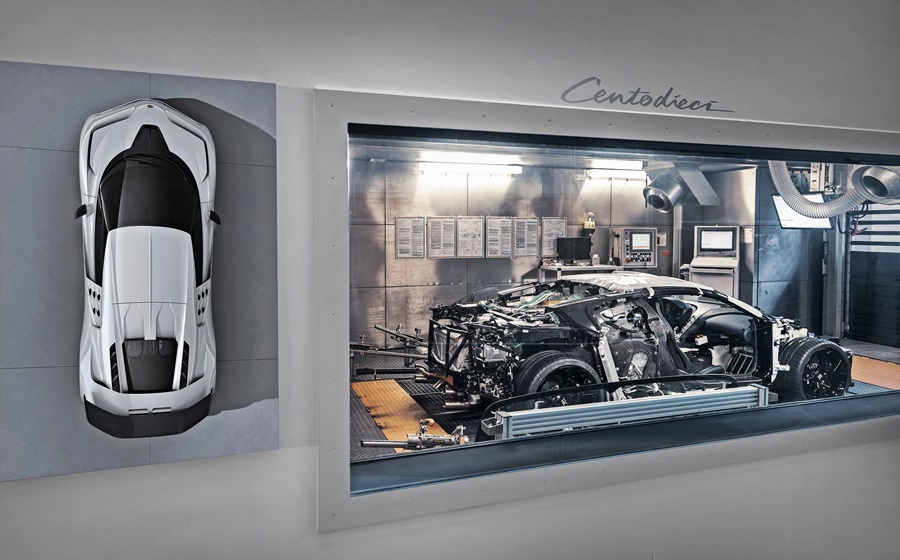

The engineers first delve into calculations of the body, aerodynamics, engine and transmission. They simulate the flow through the vehicle and check all components down to the smallest screw. At the same time, the design team works closely with the developers to control the styling, finalize it and design surfaces. Depending on the incidence of light, they adapt the curvature of the components so that they appear homogeneous in all lighting conditions – a complex development process. After well over a year of construction and simulation, the team has now developed the first prototype.

“With the newly designed body, there are changes in many areas that we had to simulate with the help of special computer programs. Using the data, we were able to set a basic set-up as a starting point for series development and the first prototype,” said Kullig.

The team was recently able to successfully put the rolling chassis into operation on the on-site roll test bench in the studio and check all functions of the. In the next step, the complex exterior is now being built.

“With such a powerful hyper sportscar like the Centodieci, the aim is to filter out subtleties that require concentrated and intensive development work due to the changed requirements of a completely new outer skin,” Kullig added.

The challenge of thermal management

The technical challenges have been enormous: an 8-litre engine with 1,600 ps generates high temperatures that require sophisticated thermal management. As with the EB 110, the engine is under a transparent glass surface. In favour of more efficient engine thermal systems, the Centodieci relies on a wide air outlet opening and modified air flows. In addition, guide flaps around the five round air inserts, placed as a rhombus, ensure sufficient air intake for the 16-cylinder unit.

The otherwise dominant Bugatti line, the ‘C line’, is therefore giving way to a new design. The rear forms a large air outlet opening shaped by the eight rear light elements. Further challenges in the development are the new lighting elements and the design of the rear wing,

But no matter how much data the development team can simulate and test on test benches, the Centodieci will also be tested dynamically. In the next few months, in addition to setting up the exterior and further simulations in the wind tunnel, there will also be road testing to start tuning the chassis.