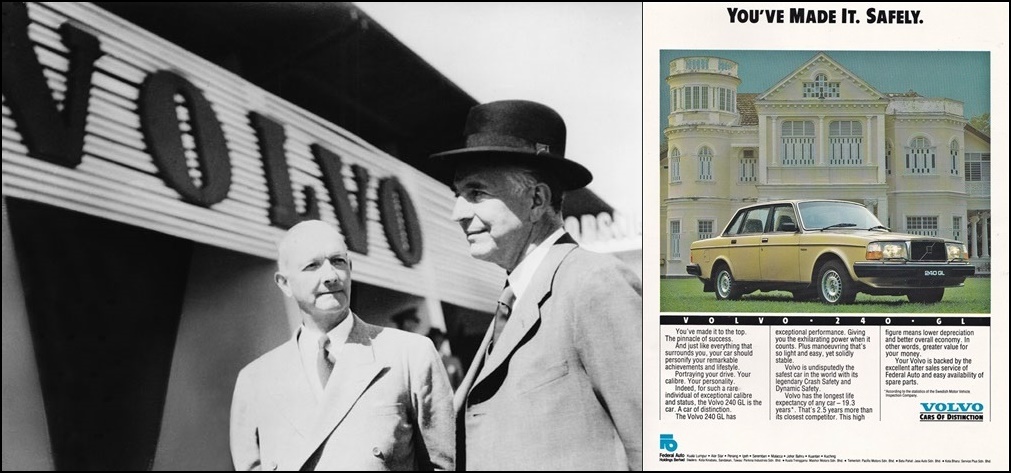

“Cars are driven by people. The guiding principle behind everything we make at Volvo, therefore, is and must remain, safety.” This was laid down by Assar Gabrielsson and Gustav Larson, the founders of the Swedish company, in 1927 and the principle has been upheld to this day. Whenever Volvo is mentioned, most people will think of ‘safety’ and indeed, its vehicles are among the safest in the world.

The company has pioneered many safety features and on average, it crashes at least one brand new Volvo a day. In earlier years, the facilities were outdoors and fairly basic – vehicles were basically driven against each other or into solid barriers to study the effects of such impacts.

Advanced crash laboratory

Eventually, crash test laboratories were built and allowed more detailed assessments with sophisticated instruments for recording and measuring. Virtually every carmaker had one and in 2000, Volvo opened its brand new Safety Centre which was one of the most advanced crash labs in the world and in many ways it still is today.

This facility helps engineers at Volvo Cars push the envelope in safety and to learn from real-life traffic accidents, as the company aims for a future in which no one is killed or seriously injured in a new Volvo.

“Being committed to safety is not about passing a test or getting a safety rating,” said Thomas Broberg, one of Volvo Cars’ leading safety engineers and a two-decade company veteran. “Our commitment to safety is about finding out how and why accidents and injuries occur and then developing the technology to help prevent them. We hope our pioneering work will inspire others to follow, our ambition to reduce road traffic casualties worldwide.”

Testing beyond regulatory requirements

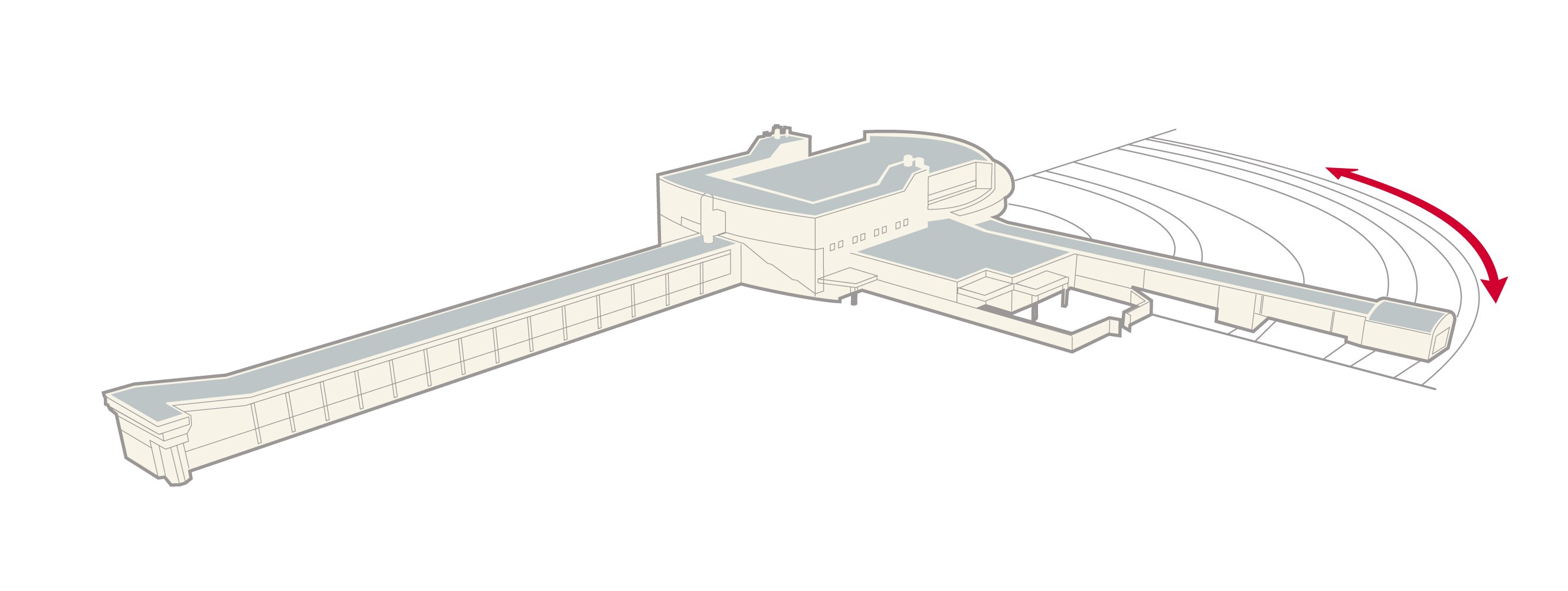

The Volvo Cars Safety Centre crash lab is a multifunctional facility that allows Volvo Cars safety engineers to recreate countless traffic situations and accidents, and perform tests that go beyond regulatory requirements.

The lab contains two test tracks of 108 and 154 metres long. The shorter of the two is moveable and can be positioned at an angle between 0 and 90 degrees, allowing for crash test at different angles and speeds, or to simulate a crash between two moving cars. Cars can be crashed at speeds up to 120 km/h.

Outside, there is room for performing tests like roll-over crashes and run-off road scenarios, whereby cars are launched into a ditch at high speeds. Here, Volvo Cars also offers rescue services opportunities to practice and develop their life-saving skills, as it did earlier this year when it dropped new Volvos from a height of 30 metres to simulate the heavy damage found in extreme crash scenarios.

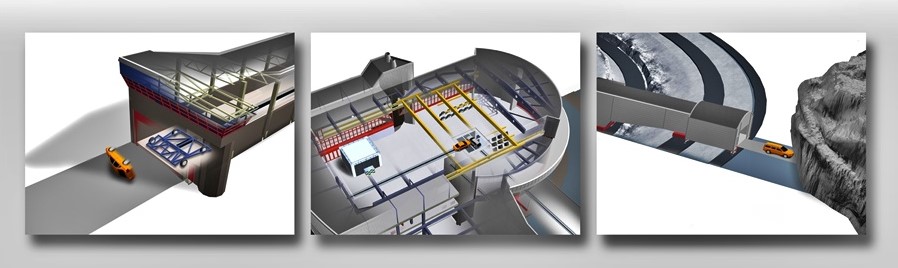

Inside the main hall, an enormous crash barrier is used for testing various frontal, rear and side impacts. Weighing an astonishing 850 tonnes, it can be moved around if needed with the help of air cushions.

Additionally, there are around two dozen other fixed and movable barriers that are used in crash testing, including a moose-like structure to simulate crashes involving these animals.

Recording what happens in an accident

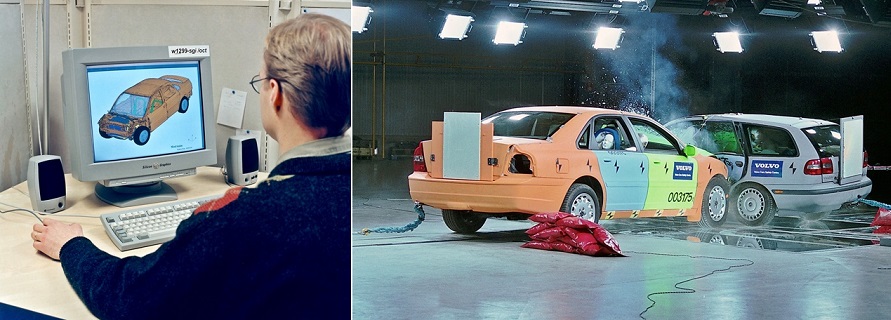

During crashes, the car, the crash test dummies and the barriers are fitted with sensors that allow engineers to register the entire chain of events in detail. Dozens of ultra-high definition and ultra high-speed cameras also film the crash test from every angle.

Before a physical crash test, the new model under development has already gone through thousands of crash tests – in computer simulations. All the data generated by these simulations, along with the physical crash tests, is then used by Volvo’s engineers as they design the cars to the highest levels of safety and protection for the occupants.

“No matter what the scenario, we can recreate it here at the Volvo Cars Safety Centre and analyse it in detail,” said Broberg. “For me, it is very inspiring to realise that for every hour of testing and analysis we put in, we get closer and closer to our ambition that no one should be killed or seriously injured in a new Volvo.”

Click here for other news and articles about Volvo.