Electrification is the big thing in the auto industry today. Manufacturers are racing to develop and offer electrically-powered vehicles as well as hybrids with electric power. Even high-performance brands like Mercedes-AMG are ‘electrifying’ in various ways to combines high efficiency with additional driving dynamics.

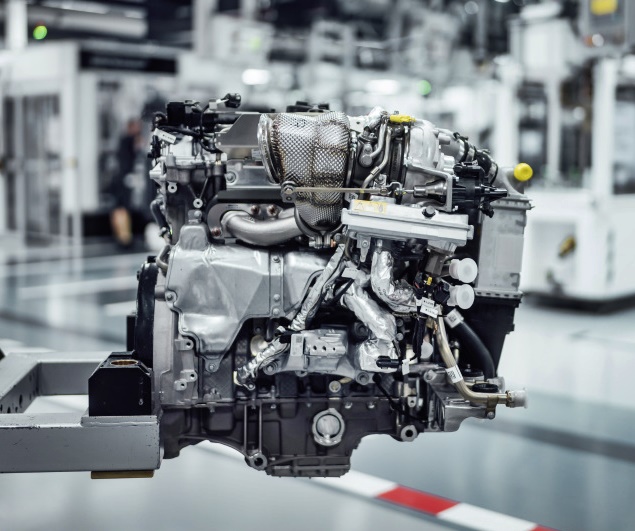

To implement this combination to optimum effect, the developers in Mercedes-AMG are working intensively on innovative technologies which will see the next vehicle generation use an electric exhaust gas turbocharger.

Of course, with its active involvement in motorsports, Mercedes-AMG can draw on the solutions and technologies from its racing cars. The electric exhaust gas turbocharger is in its final stages of development and will soon be installed in a production model.

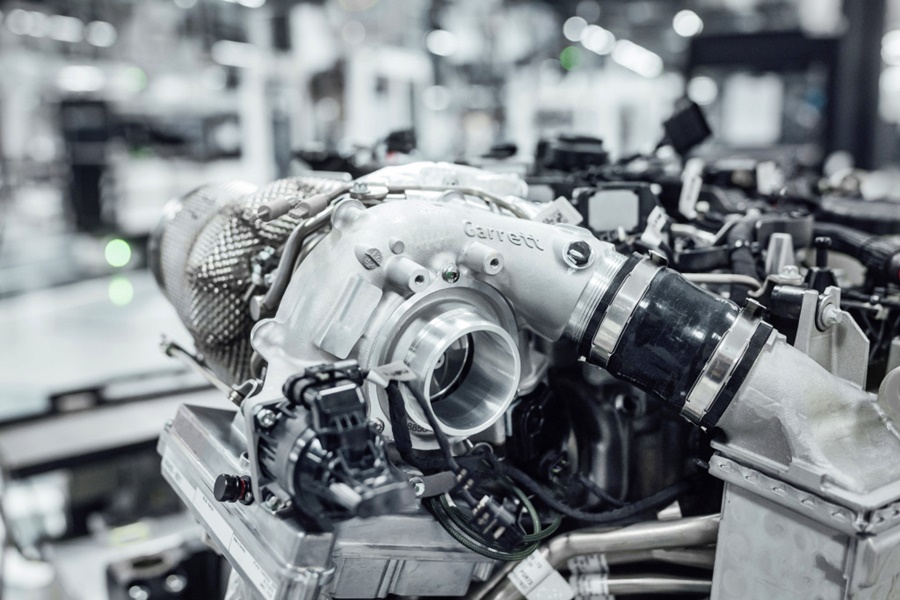

Mercedes-AMG is working with Garrett Motion and the engineers have resolved the conflicting goals between a small, fast-reacting turbocharger which achieves relatively low peak performance and a large turbocharger with a high peak performance but which, on the other hand, can suffer from turbo lag.

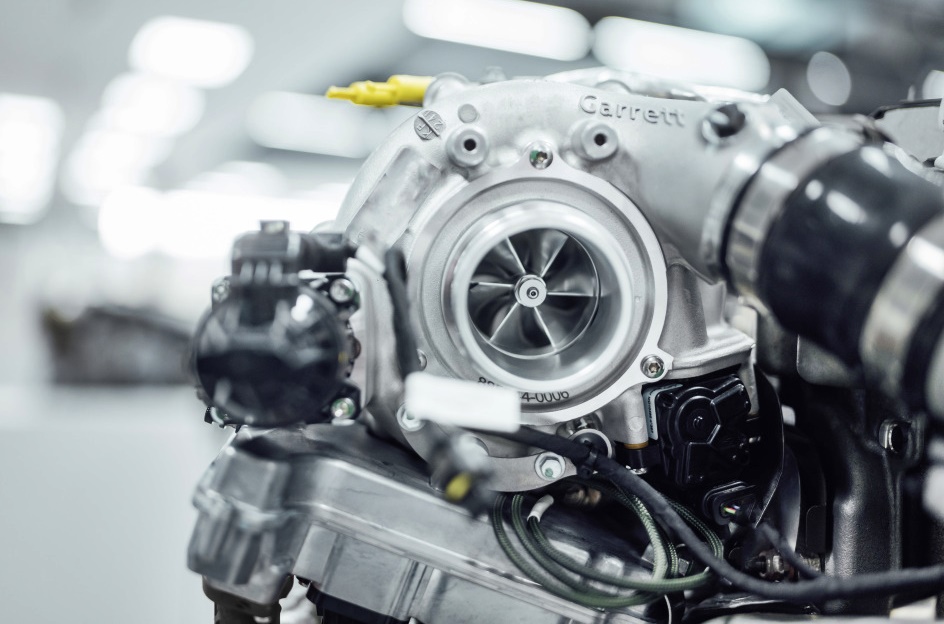

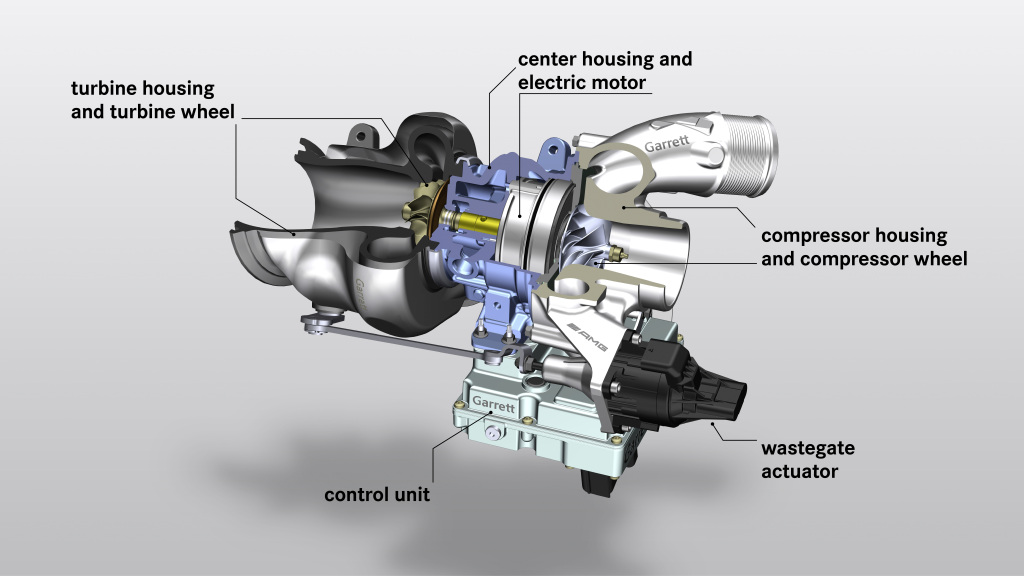

The highlight of this innovative turbocharging system is a slim electric motor, measuring about 4 cm, which is integrated directly on the charger shaft between the turbine wheel on the exhaust side and the compressor wheel on the fresh air side. This electronically-controlled electric motor drives the compressor wheel before this accepts the exhaust gas flow.

The electrification of the turbocharger significantly improves immediate response from idle speed and across the entire engine speed range. The so-called turbo lag – the delayed response of a conventional turbocharger – is eliminated by the electric motor. The result is that the combustion engine responds even more spontaneously to accelerator pedal input, and the entire driving feel is significantly more dynamic and agile.

In addition, electrification of the turbocharger enables higher torque at low engine speeds, which also enhances agility and optimises acceleration capability from a standstill. Even when the driver takes their foot off the accelerator or applies the brakes, the technology of the electric turbocharger is able to maintain the boost pressure at all times, so that a continuous direct response is guaranteed.

The turbocharger can spin up to 170,000 rpm, which enables a very high rate of airflow. It can be operated via a 48-volt on-board electrical system. The turbocharger, electric motor and power electronics are connected to the combustion engine’s cooling circuit to create an optimum temperature environment at all times.

“We have clearly defined our goals for an electrified future. In order to reach them, we are relying on discrete and highly innovative components as well as assemblies. With this move we are strategically supplementing our modular technology and tailoring it to our performance requirements. In a first step this includes the electrified turbocharger – an example of the transfer of Formula 1 technology to the road, something with which we will take turbocharged combustion engines to a previously unattainable level of agility,” explained Tobias Moers, Chairman of the Board of Management of Mercedes-AMG.