BMW Efficient Dynamics technology was initiated in 2007 with the objective of consistently reducing fuel consumption – and thereby CO2 emissions – on the one hand, while steadily enhancing driving dynamics on the other. Generally, when pursuing lower fuel consumption goals, the trade-off has been in performance but that would not be acceptable to BMW engineers.

As a result, Efficient Dynamics is now a fundamental link in the DNA of all BMW models and one of the key reasons why the BMW Group will be able to meet the European Union’s CO2 targets in full.

Technical measures covering every area

The Efficient Dynamics approach systematically optimizes every aspect of the vehicle, not just the powertrain. On the aerodynamics side, active air flap control is now in its third generation, while the new iX3 (due to be launched by the end of 2020) will be fitted with the latest generation of BMW aerodynamic wheels.

The technology behind the new wheels has been further refined, resulting in a 5% reduction in drag coefficient compared to conventional X3 wheels plus a 15% weight saving over the previous BMW aerodynamic wheel type.

Such significant steps forward have been achieved thanks to heavy investment in the necessary aerodynamics R&D infrastructure over recent years. The most aerodynamically efficient current model overall, the new 3-Series Sedan, has a Cd of just 0.23, earning it the title of ‘best in segment’.

Intelligent lightweight design has also led to some major efficiency-boosting advances. This has made it possible to reduce the weight of models from one generation to the next, despite increases in size and safety enhancements. Optimizing structures and employing the ideal materials in every area of a vehicle are key to attaining the goals that have been set.

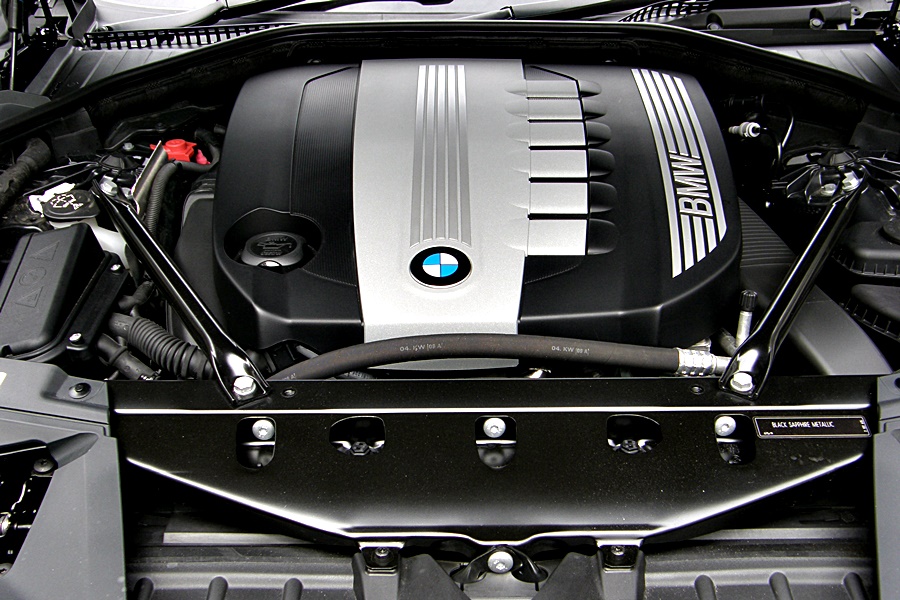

The wide range of powertrain systems on offer also plays a fundamental role in the Efficient Dynamics concept. From highly efficient combustion engines with 48V electrical systems to plug-in hybrids and all-electric vehicles – all are underpinned by the basic principle of Efficient Dynamics: minimize the input while maximizing the output.

The advent of 48V mild hybrid technology greatly expands the possible uses of Brake Energy Regeneration. This technology made its debut in the four variants of the 520d last year and are now being extended to the 3-Series, X3 and X4 ranges.

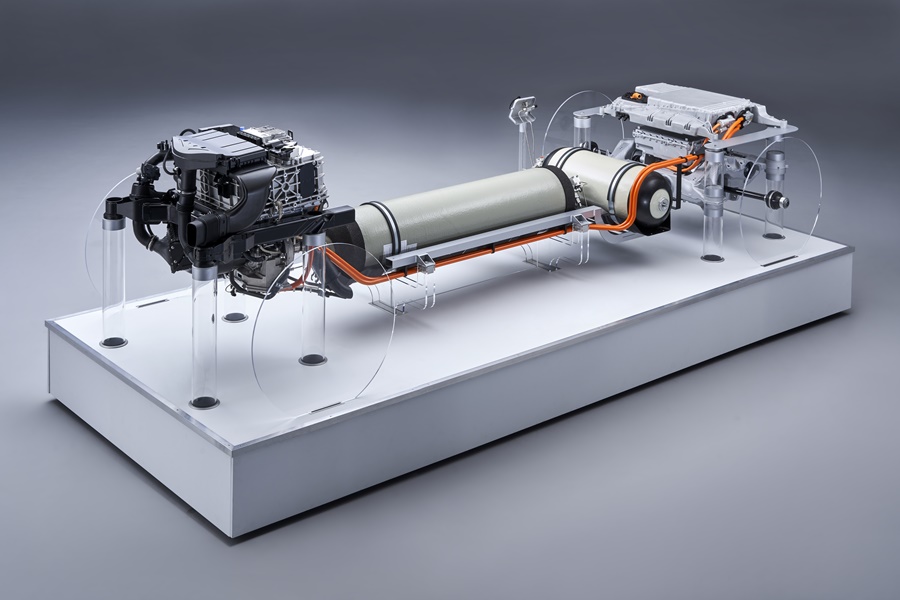

Hydrogen fuel cells in future

The BMW i Hydrogen NEXT – unveiled to the public at the 2019 Frankfurt Motor Show as a technology demonstrator – represents a potential fourth pillar in the company’s powertrain portfolio. The BMW Group has been working with the Toyota Motor Corporation on fuel cell technology since 2013. The underlying conditions for supplying ‘green’ hydrogen are not yet in place, however, meaning it will still be some time before the BMW Group brings out a production vehicle with this technology on board.

Systematic roll-out with clear benefits

As a result of the continuously evolving package of technological measures, fleet consumption and CO2 emissions have been cut by more than 40% over the last 13 years. What is more, the BMW Group will comply in full with the European Union’s CO2 targets, thanks in part to the rigorous deployment of BMW Efficient Dynamics innovations as standard across all model series. With ongoing electrification of the range, CO2 emissions in 2020 will be 20% lower again thant the figure for 2019.

First look at the hydrogen fuel cell powertrain being developed by BMW and Toyota