Before 1980, mention of ‘4-wheel drive’ referred to vehicles like Land Rovers, Jeeps and Land Cruisers, with all four wheels being powered to provide maximum grip on all kinds of surfaces. These vehicles were mainly intended for off-road use in rough conditions. Performance on highways was not their strong point and in any case, they didn’t go very fast either.

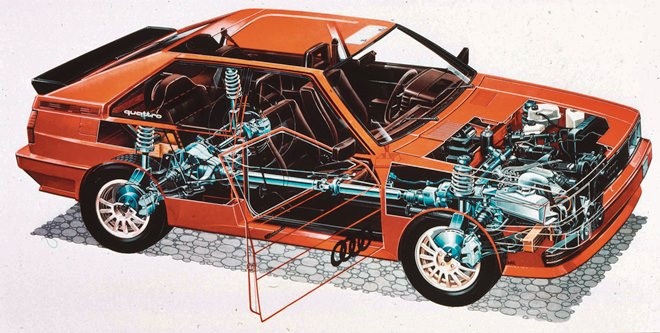

Then Audi came out with a system which it called ‘quattro’, bringing the concept of all-wheel drive to roadgoing vehicles which could provide superior grip on any road surface in dry or wet weather.

The idea of quattro stemmed from the desire to mass-produce cars with traction to all four wheels, with Audi engineers first developing a lightweight all-wheel-drive system based on the fundamental traits demonstrated by the Volkswagen Iltis off-roader in the 1970s. The technology was then advanced under the Audi brand in 1980 with the first production quattro all-wheel-drive system.

The superiority of the quattro system was very quickly demonstrated when Audi entered the World Rally Championship and started beating everyone, bringing the brand numerous titles. Following that, it also helped Audi win IMSA and Trans-Am races in America with sedan models. There was no doubt in anyone’s mind that all-wheel drive was a game-changer, a performance-enhancer which became a feature of high-performance models.

The quattro evolution

The quattro system defines Audi in many ways and remains its unfair advantage on the road and racetrack. Today’s quattro system builds on the 40 years of experience, with several different types available in various applications. But before getting to today’s drivetrains, it’s important to understand how earlier quattro systems worked.

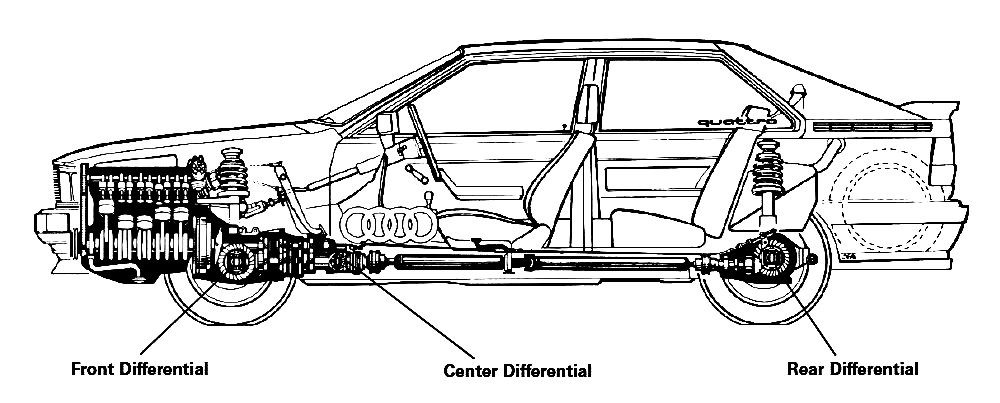

The first quattro system used three mechanical differentials to distribute torque between the front and rear wheels. Via a vacuum-operated switch, the driver could select to lock the centre differential to lock the front and rear differentials together, causing them to turn at the same speed without slip.

Ordinarily, the differential — a set of gears driving the wheels at each axle — are fully open to help compensate for the difference in speed each wheel travels. Think of taking a corner, for instance: the inside wheel will rotate far less than the outside wheel. Locking the rear differential helps ensure power gets to both wheels equally, which is needed when driving on slick surfaces or traction-limited situations but also to maximize grip in any condition. The front does not have a locking differential because of the need to turn.

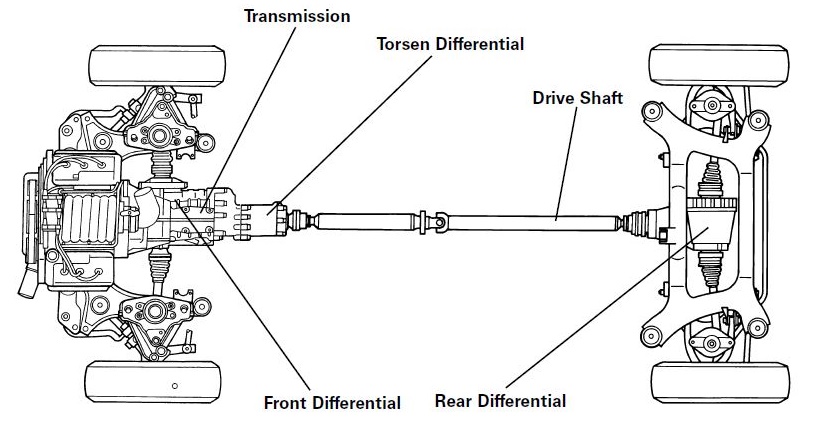

In the first major update of quattro in the late-1980s, a Torsen (short for torque-sensing) differential that automatically split power 50:50 from front to rear replaced the original manually-operated centre differential. A rear differential lock switch remained; some larger models were available with a rear Torsen differential as well.

The Torsen differential housed a pair of helical planetary gears. The gears were held in tight-fitting pockets inside the housing and splined together through spur gears at their ends. These spur gears did not allow the planetary gears to rotate in the same direction. However, when an axle would lose traction, the spur gears would help channel torque to the wheels with traction. This could allow up to two-thirds of the vehicle’s torque to be sent to either the front or rear axle.

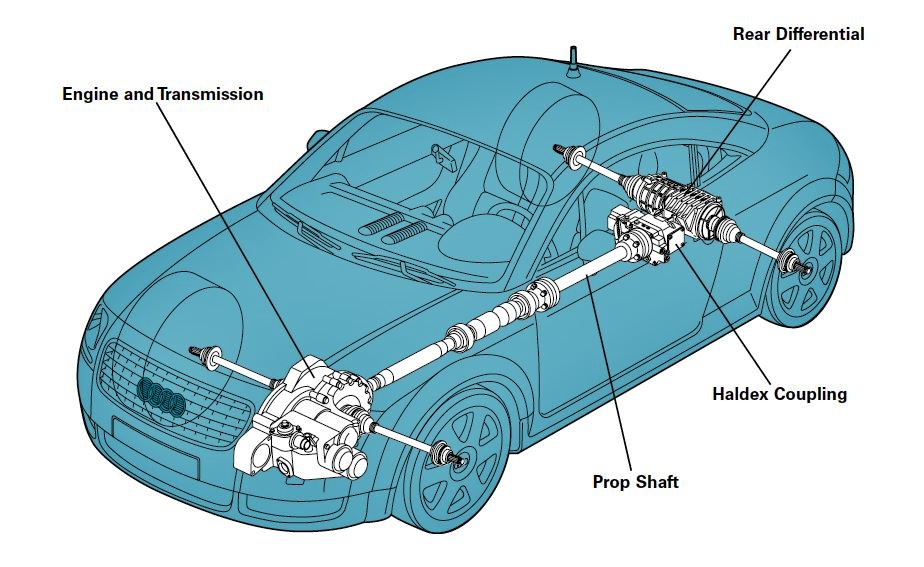

Haldex – not averse to being transverse

Medium and large Audi models have a longitudinal engine, with their transmissions and differentials sitting behind the engine. Starting in 2000 in the USA, smaller models like the Audi TT came with their engines sitting in a sideways or transverse orientation. As a result, their transmissions took up space practically underneath the engine, necessitating a different sort of quattro system.

This is where the Haldex coupling came in as an answer to the packaging needed for this sort of application. In a Haldex application, a propshaft runs from the transmission to the rear differential. The end of the propshaft connects to the input shaft of the Haldex coupling. The end that connects from the Haldex coupling to the differential is called the output shaft. On a slippery driving surface, one or more wheels may have reduced traction. As a result, the Haldex coupling senses a difference in speed between the input and output shafts and takes action.

Sensors reading engine speed, accelerator pedal position and engine torque also participate in the activation of the rear differential. In addition, Electronic Differential Lock utilizes the ABS system to control loss of traction at each individual wheel.

Today’s quattro system

Today, Audi offers 5 unique quattro technologies, all based on the same fundamental understanding of how quickly an all-wheel-drive system needs to respond — and with how much power to each wheel — for maximum grip and performance. The systems are as follows:

quattro all-wheel drive for medium and large models using the MLB evo architecture (8-speed Tiptronic (torque-converter automatic transmission) and 7-speed S tronic (dual-clutch automatic transmission)

quattro all-wheel drive with ultra technology (7-speed S tronic) using the MLB evo architecture

quattro all-wheel drive for transverse applications using the MQB architecture

quattro all-wheel drive for the Audi R8 using the MSB architecture

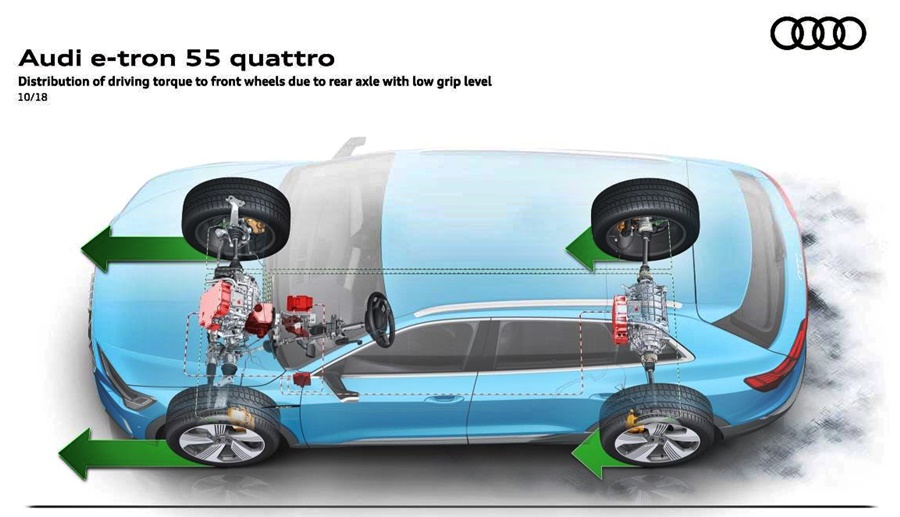

e-tron electric quattro all-wheel drive (shown below), using electric motors on each axle

Fundamentally, quattro all-wheel drive for Audi medium and large cars works similarly to previous systems with three differentials. Now, it is mechanically as well as electronically activated, and it distributes torque to wheels based on steering angle sensors, traction and stability control, yaw sensors (measuring how weight shifts left or right around its centre of gravity) and wheel sensors.