Like many carmakers, General Motors is heading for an all-electric future and putting considerable resources into building a multi-brand, multi-segment EV strategy with economies of scale that can rival its full-size truck business. By right, the company should be way ahead in the EV field today, having come out with the first mass-produced all-electric car, the EV-1, in 1996.

However, advanced as it was, the car was expensive to produce, and GM saw the EV segment then as being unprofitable, so it stopped making the car. Developing EVs then was not a priority (engineers who were assigned to such projects considered them ‘dead-end jobs’) and so GM didn’t advance its EV technology the way Toyota had done so with its hybrid technology after it introduced the Prius in the late 1990s.

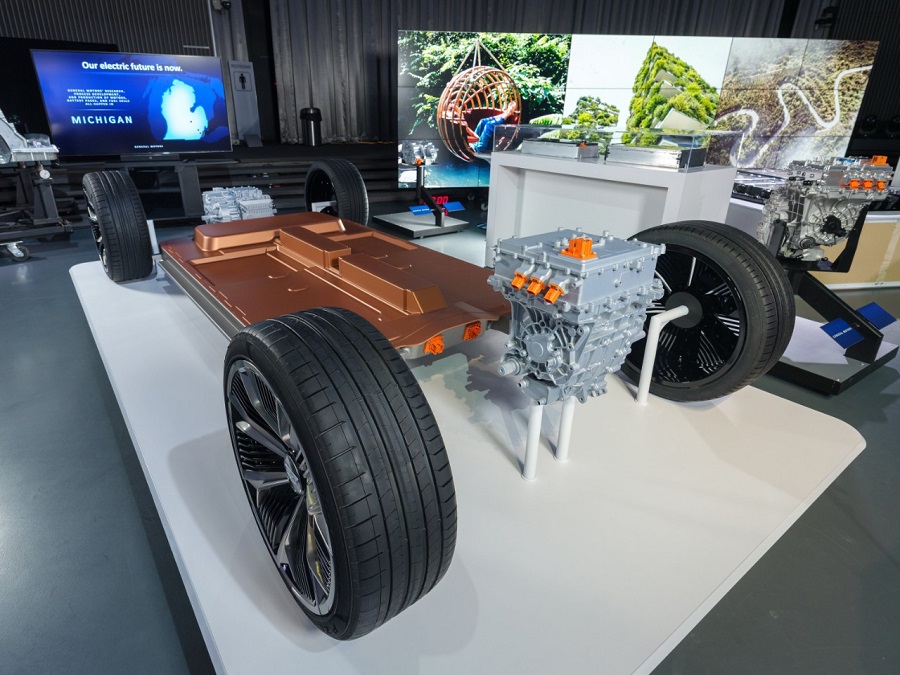

Now GM is accelerating its R&D into EV technology and the heart of its strategy is a modular propulsion system and a highly flexible, third-generation global EV platform powered by proprietary Ultium batteries.

“Thousands of GM scientists, engineers and designers are working to execute a historic reinvention of the company,” said GM President Mark Reuss. “They are on the cusp of delivering a profitable EV business that can satisfy millions of customers.”

The Ultium batteries and Propulsion System

GM’s new Ultium batteries are unique in the industry because the large-format, pouch-style cells can be stacked vertically or horizontally inside the battery pack. This allows engineers to optimize battery energy storage and layout for each vehicle design.

Ultium energy options range from 50 to 200 kWh, which could enable a GM-estimated range up to 640 kms or more on a full charge with 0 to 100 km/h acceleration as low as around 3 seconds. Motors designed in-house will support front-wheel drive, rear-wheel drive, all-wheel drive and even performance all-wheel drive applications.

Ultium-powered EVs are designed for Level 2 and DC fast charging. Most will have 400-volt battery packs and up to 200 kW fast-charging capability while the truck platform will have 800-volt battery packs and 350 kW fast-charging capability.

Driving costs downwards

The flexible, modular approach to EV development is expected to drive significant economies of scale for lower production costs and create new revenue opportunities. The cells use a proprietary low cobalt chemistry and ongoing technological and manufacturing breakthroughs will drive costs even lower. Together with LG Chem, its joint venture partner, GM sees continuous improvement in battery costs as they are driven down to US$100/kWh.

GM’s all-new global platform will be flexible enough to build a wide range of trucks, SUVs, crossovers, cars and commercial vehicles. To build them with capital efficiency, GM will leverage on existing properties, including land, buildings, tools and production equipment such as body shops and paint shops.

The vehicle and propulsion systems are designed together to minimize complexity and part counts beyond today’s EVs, which are less complex than conventional vehicles powered by internal combustion engines. For example, GM plans 19 different battery and drive unit configurations initially, compared with 550 internal combustion powertrain combinations available today.

Third-party forecasters expect EV volumes in the US market to more than double from 2025 to 2030 to about 3 million units on average. But GM believes the numbers could be materially higher as more EVs are launched in popular segments, charging networks grow and the total cost of ownership to consumers continues to fall.

The Hummer is returning but you’ll hardly hear it coming… (w/VIDEO)