Perhaps you may not have realised it but many years after a model has ceased to be produced, genuine parts from the manufacturer are still available from its own service centres or authorised parts stockists. Some may be surplus stock but there will also be many parts that continue to be made after production of the model (or generation) had stopped. This ensures that subsequent owners of the model can still get genuine parts which are made to the same high quality standards as when the model was still in production.

It’s a sort of ‘unwritten’ industry practice that parts for a model will continue to be available from the manufacturer for at least 10 years after the end of production. For a market leader like Perodua, which has been producing cars since 1994 and put over 3.7 million vehicles on Malaysian roads, there’s a major responsibility to ensure that the parts remain available. This is especially so in Malaysia where there is still no ‘end-of-life’ policy so cars tend to be used for a long time.

One-third of parts demand for old models

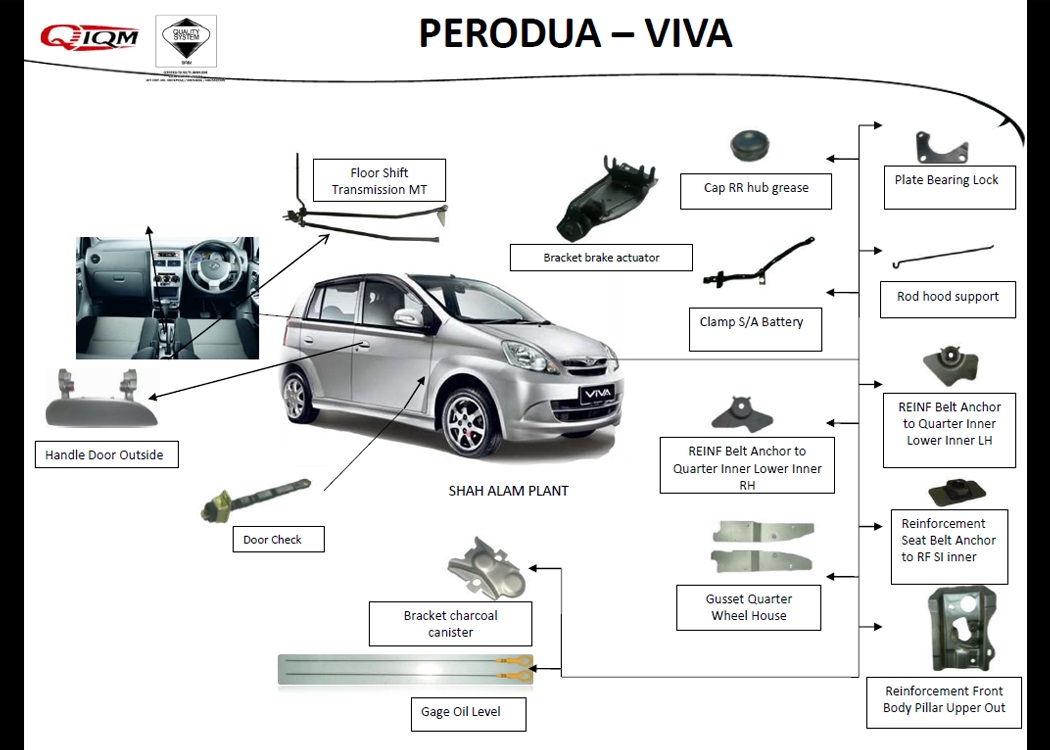

Currently, a third of the demand for Perodua parts is for past models such as the first-generation Myvi, Viva, Kelisa and even the Kancil. Besides making the parts at its own factory complex, Perodua has also assigned some parts to Industrial Quality Management (IQM) Sdn Bhd, its supplier since 2002. IQM currently supplies metal stamping, body assembly parts and brake tube components to Perodua. It also began making Viva parts when production of the model ended in 2014 and last year. it began making parts for the second-generation Myvi on a dedicated new line.

Today, Perodua announced that it is centralising parts production for its past models with the launch of a new press stamping machine at its facility within IQM’s factory located in Tanjung Malim, Perak. The move is one of Perodua’s many initiatives with its suppliers to help expand their business and capabilities, bringing them one step closer to becoming global automotive suppliers.

Freeing up space and simplifying operations

At the same time, this frees up much-needed space in Perodua’s complex, simplifies the entire operation, reduces lead time and cost, and makes it easier to monitor under one roof. Perodua also assists IQM in terms of skill transfer and training where past model parts production is concerned.

A RM7 million investment on the machine, including its transportation and installation, was made by Perodua entirely. The 1,600-metric tonne hydraulic press stamping machine will produce body parts such as bonnets, side outer panels, rear quarter panels, fenders, doors and roofs for past Perodua models. The dies required to make the past model parts have also been moved to IQM.

Supporting owners of past models

“Perodua’s decision to centralise past model parts production at IQM is 4-pronged. One, we want to continue supporting owners of our past models with quality, quick and affordable parts through our Body & Paint business, because as long as you own a Perodua vehicle – old or new – we will always be there for you,” said Perodua’s President & CEO, Dato’ Zainal Abidin Ahmad.

“Two, we are committed to empowering all 135 of our Malaysian suppliers, not just by buying from them but helping to develop them via skill and technology transfers. Three, it represents our commitment to the nation and its economy by helping to boost the competitiveness of the Malaysian automotive eco-system,” he added. “Finally, it represents our commitment to ourselves. To keep improving our quality and efficiency so that Perodua can be a better and leaner company moving forward,”

With all its current models having over 90% of parts purchased locally, Perodua is naturally the biggest buyer of automotive components in the country. It has spent RM4.5 billion on parts so far this year out of a planned RM5.4 billion for the whole of 2019.

Visit www.perodua.com.my to locate a service centre where you can purchase Perodua Genuine Parts.