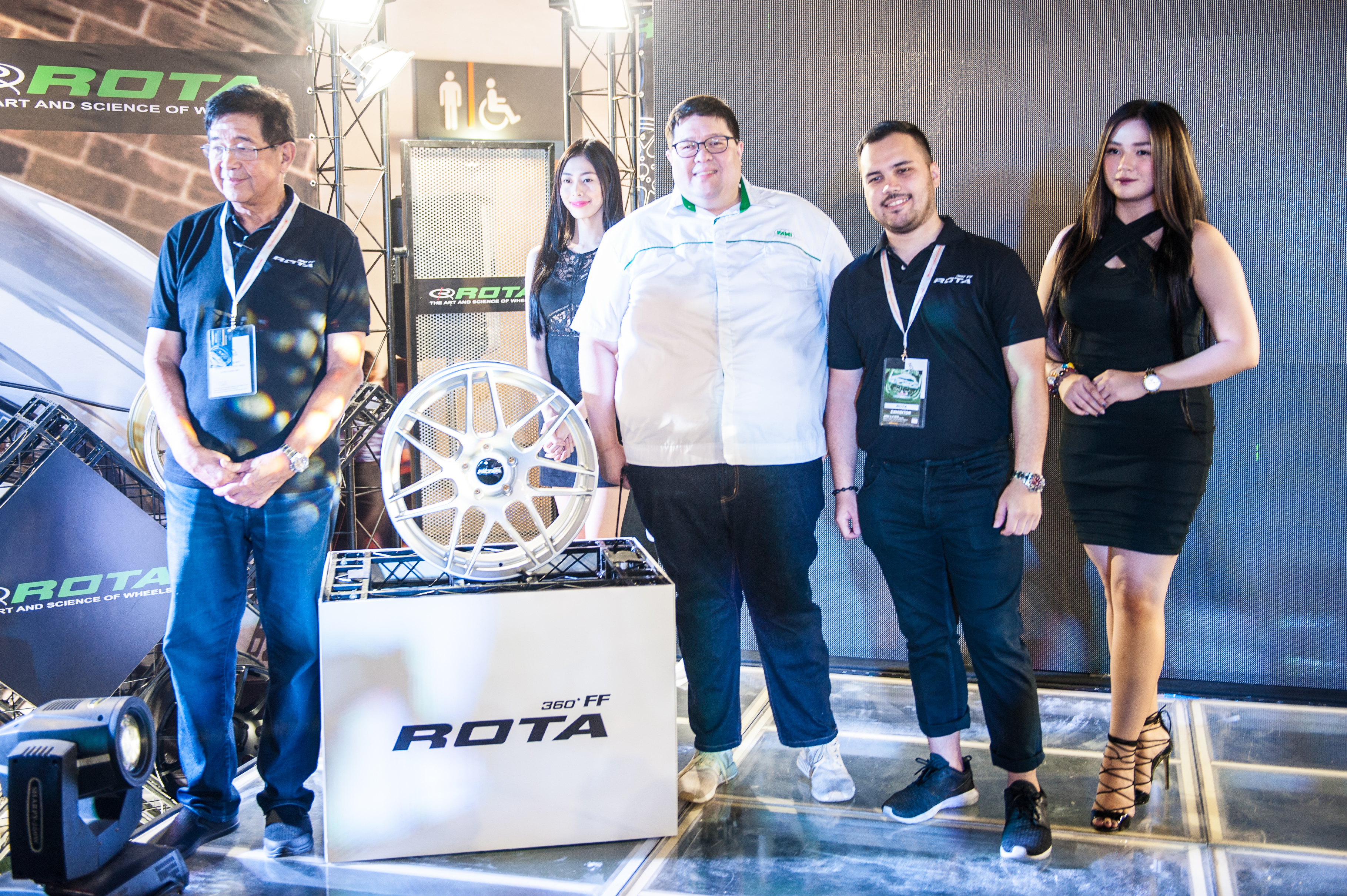

Did you know that famed alloy wheel maker ROTA, a favourite of boy-racers and professionals alike, is from The Philippines? With over 40 years of experience in wheel manufacturing, Philippine Aluminum Wheels, Incorporated (PAWI), manufacturer of Rota Wheels, is taking the art and science of wheels to the next level. With the launch of the Rota 360-degree Flow Forged Wheels, it presents a new revolution (pun intended) for wheel manufacturing in the Philippines.

“We are very excited to introduce the Rota 360-degree Flow Forged Wheel,” said Mr. Michael S. Rojas, President of PAWI. “Our new wheel is lighter, denser, and more durable than our high quality gravity cast wheels. And because it’s Rota, it’s very affordable too.”

The Rota 360-degree Flow Forged wheels are made through a process called flow forging, a first in the country. This is done by gravity casting virgin ingots of high-grade aluminum, which is then heated and spun to form the wheel. In effect, flow forging combines the elements of making a cast wheel and a forged wheel, making it lighter and stronger than a cast wheel. That means less unsprung weight and, therefore, improves vehicle dynamics and handling. And it does all that by further enhancing a wheel’s durability under tough conditions.

As with all Rota wheels, the 360-degree Flow Forged wheels have undergone a battery of vigorous testing. Impact, cornering and radial tests are carried out on the wheels to ensure a high caliber of quality the company has been known for, and give customers peace of mind. With testing methods that follow international standards, your Rota wheels will keep on rolling and the 360-degree Flow Forged wheels are no exception.

The Rota 360-degree Flow Forged line will be available soon, both locally and abroad. Set to be released through the company’s extensive domestic and international network, the world will soon experience a Philippine revolution as Rota forges into the future, pun intended again, further evolving the art and science of wheels.