The advent of 3D printing has led to the simplification and reduction in time needed for prototyping. Take 3D printed plastic structures for example, using the conventional method is very time consuming.

It used to be an arduous process of developing and building a mold, mixing various compounds together to develop a resin, then pouring that into the mold and allowing it to cure. It took time, and every time a change needed to made, a new mold would have to be produced and the entire process restarted.

Well, with 3D printing, all you have to do is make the adjustments to the 3D model on your PC using the appropriate software, and once complete, send that information to the printer to begin the printing process. Depending on the complexity of the modeling, the structure should be complete in considerably less time than that needed with the conventional method.

Now, that same technology has been adapted for the automotive world as well. A company called Divergent 3D, a US based firm, have successfully used 3D printing to develop and build a fully functional supercar with 700 bhp, called the Divergent Blade. They actually managed to print the entire metal structure of the car with their propriety construction methods.

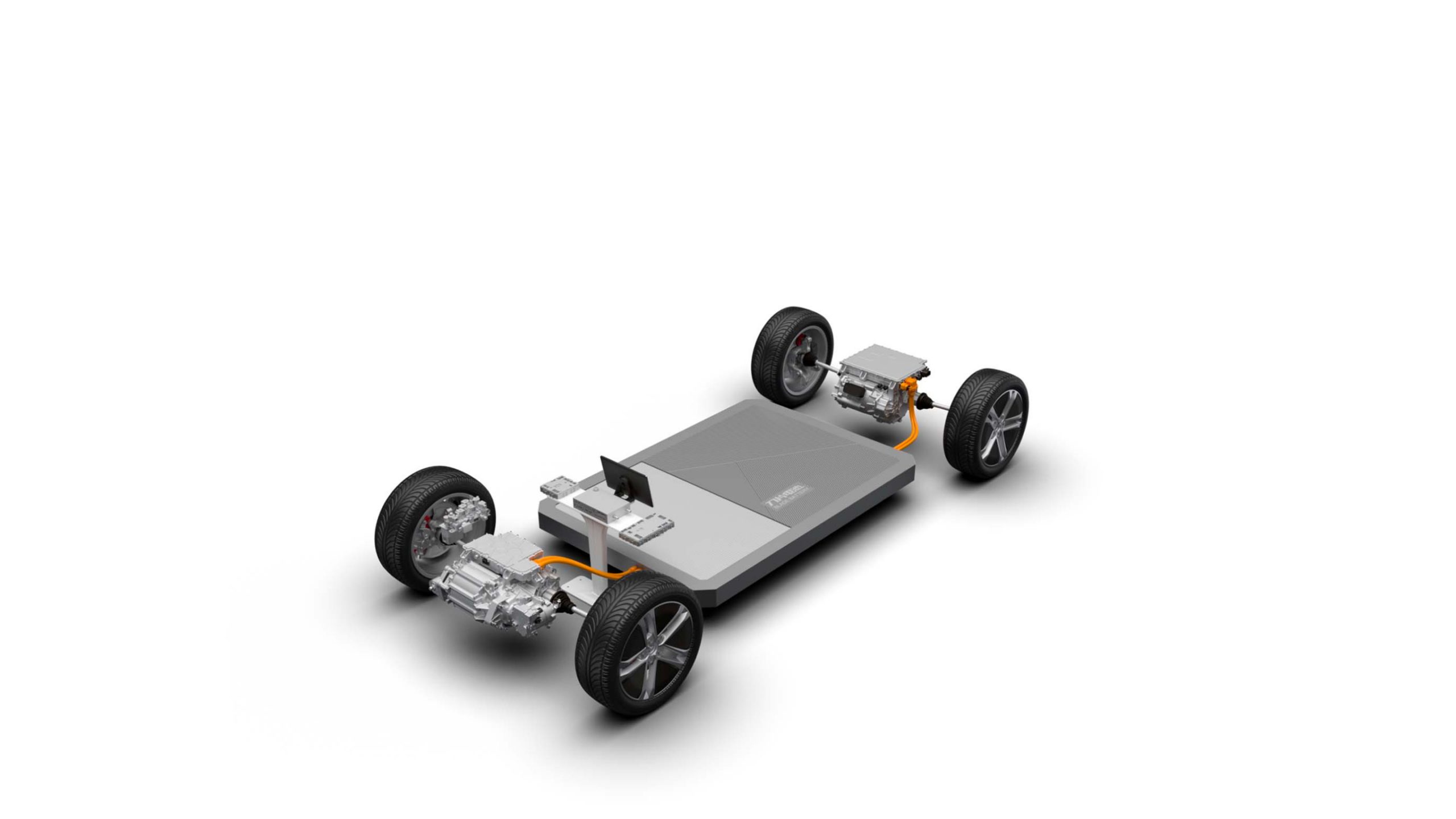

Unlike conventional cars, this has a body on frame design where a chassis with all its mechanical bits fully attached to it, is mated with a top shell, which in this case is the car’s body. It’s an approach that the company believes saves time and valuable resources compared to the methods used by big name automotive manufacturers. And as such, this Divergent Blade, is a prototype that may open the eyes of many automakers and nudge them to change their processes and in turn offer vehicles at a much cheaper price.

CEO and Founder of Divergent 3D showcased the car during and episode of Jay Leno’s garage, take a look at the video and let us know what you think.